Lean for the Lean’s Sake: Not Aligned to Organizational Goals – is a story that is all too familiar.

There’s a story shared among lean practitioners that illustrates the dogmatic approach to lean manufacturing that, in part, has given lean the perception that it is detached from anything important to the organization. In other words, when a Lean Transformation doesn’t align to organizational purpose, it becomes a detached and misaligned effort. This leads to apathy, misunderstanding, and eventually, failure. The story that illustrates my point goes like this.

Heroic Act of Reducing Changeover Time

Supposedly, a few ex-Toyota folks were hired to do some consulting for a company. These ex-Toyota employees visited the facility to do a quick assessment and evaluate what exactly needed to be done and what the company expected of them. At the facility, they met with the companies’ internal lean office or Kaizen office personnel. During their Gemba walk, the internal Kaizen Office associates proudly took the Toyota visitors to a recent the team had facilitated.

A week previous, the Kaizen Office had wanted to implement SMED and found a great forum to apply Single Minute Exchange of Die. It turns out the facility had this massive machine where the changeover time was around 8 hours. After the Kaizen Office was done with it, they had reduced Changeover Time from 8 hours to 15 minutes.

Proudly and expectantly, the Kaizen Office associates waited to see the smiles and admiration from the ex-Toyota visitors. But instead of praise for the reduction in Changeover Time, the ex-Toyota visitors asked this question:

How often is this machine used?

Surprised at the question, the internal Kaizen Office associates answered reluctantly,

We’re not sure, but we believe about 1 or 2 times per month.

Then, the ex-Toyota associates responded:

Was this the best use of your time?

The Lesson

There are many lessons in this short anecdote:

- The internal Kaizen Office associates began with the goal “how can we implement SMED?” That approach is very tool-focused and, that approach, leads to a very detached and disjointed application of Lean.

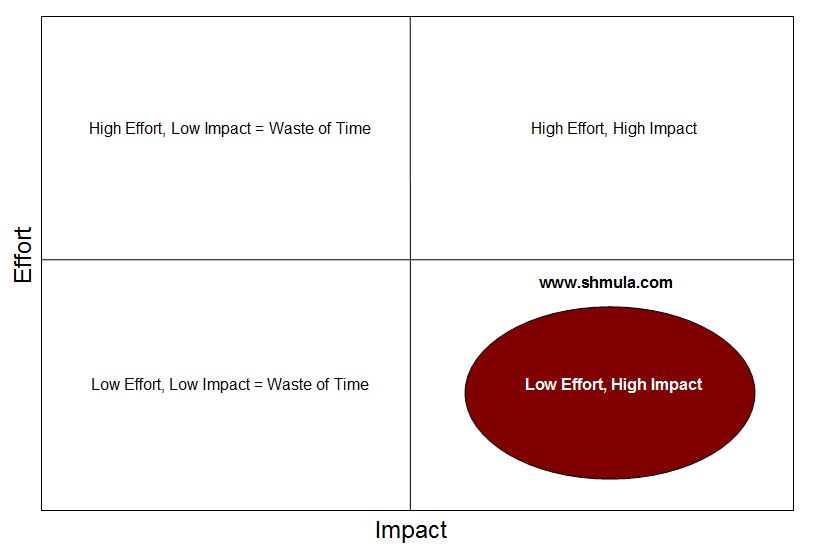

- When the organizational purpose is poorly understood, it leads to spending time where it doesn’t count. This approach fundamentally means that we are either spending time in areas that are:

- High effort, but low impact

- Low effort, but low impact

- While the application of an approach is, in itself, something to be celebrated, it also leads to a misguided approach in deploying and tranforming a company toward a lean culture.

It’s Your Turn

Is your application of Lean or Six Sigma similar to the story above? Are you spending time where it matters most to the company?

Great story, Pete.

I saw a guy present at ASQ this week and he had some survey data that showed (and this make sense) that companies who do Lean just to copy their industry peers tend to fail with Lean. Not sure where he got the data from though.

Classic case of trying to implement lean tools rather than focusing running a business. People need to forget trying to drive lean through assessments and road maps that are based on tool and concept utilization…and instead let the business drive the need. What is your business telling you it needs?

Excellent call-out that I see time and time again. “Point Kaizen”, regardless of the “point” often provides little or no value. Kaizen must be done in conjunction with Hoshin Kanri.